VLS 3.60DT

Uniquely Universal Features

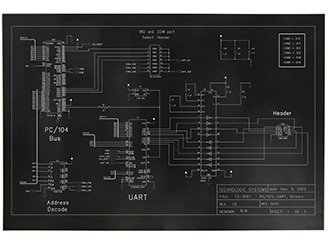

Laser Interface+™

Universal Laser Systems has developed the world’s most advanced, powerful and fexible laser print driver.

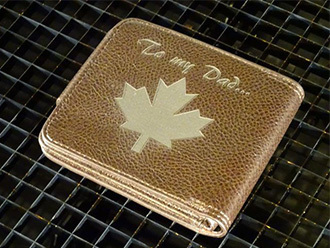

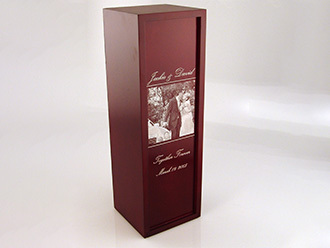

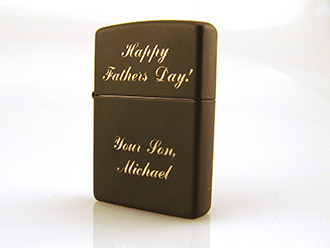

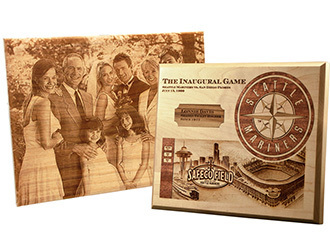

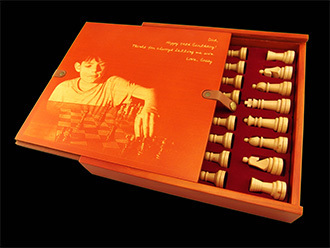

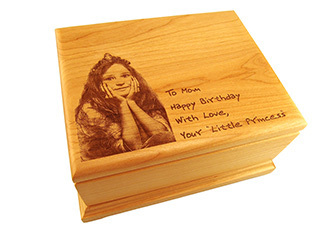

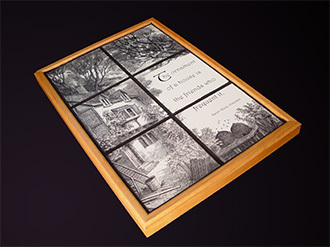

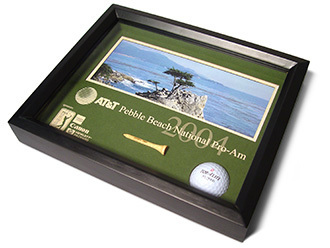

1-Touch Laser Photo™

We developed this software to make any photographic image suitable for laser engraving.

Universal Laser Cartridges

Our exclusive line of patented CO2 Free-Space Gas Slab Lasers is designed specifically for the needs of laser cutting, engraving, graphic imaging and marking applications.

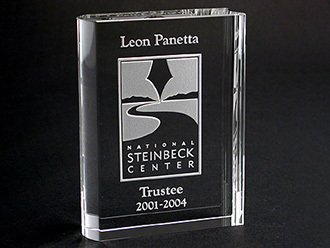

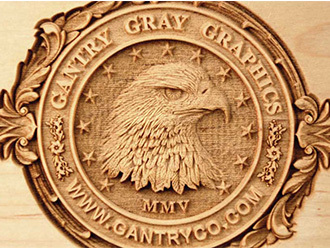

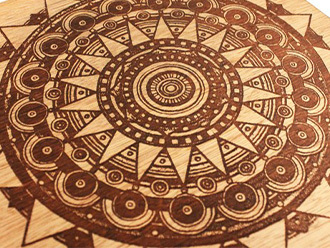

High Power Density Focusing Optics™

These optics allow the laser beam to be focused to a much smaller spot, producing sharper images at tighter tolerances.

Rapid Reconguration™ of Lasers

Every laser cartridge we produce is factory pre-aligned for easy integration into any of our laser platforms.

System Features

- Laminated Safety Glass

- Over-temp Alarm (for fire safety)

- Multiple Automatic Focusing Modes

- Precision Digital Motors

- Multiple Language Support

- Permanently Sealed Bearings

- Proportional Pulse Control

- Stretch-Free Kevlar® Belts

Laser Features

- Laser Fan Control (to reduce noise)

- Smart Lasers

- Laser Pointer

- Wide Selection of Power Levels

- Air-Cooled Laser Cartridge

- Patented Permalign™

- No Optical Beam Alignment Required

- Patented Cross-Platform Compatibility

- Patented Free-Space Gas Slab Laser Design

- High Reliability, Excellent Power Stability

- Warranty Available Up To 5 Years

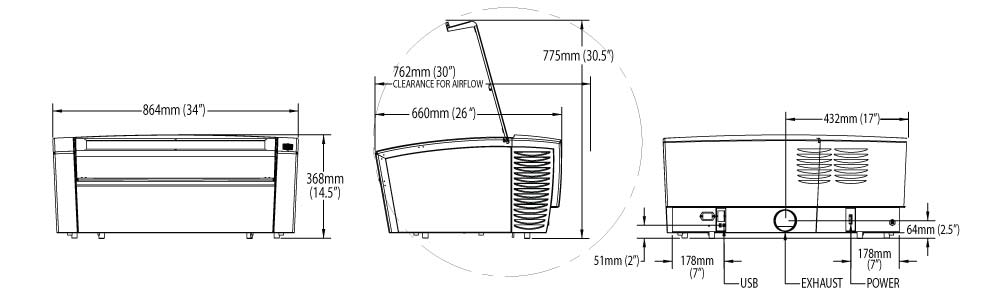

Platform Specifications

| VLS 3.60DT | |

| Laser Material Processing Area (W x H) | 24 x 12 in (610 x 305 mm) |

| Maximum Part Size (W x H x D) | 26.75 x 14.6 x 4 in (679 x 370 x 102 mm) |

| Overall Dimension (W x H x D) | 34 x 14 x 25 in (864 x 356 x 635 mm) |

| Rotary Capacity | Max Diameter: 4.0 in (102 mm) Min Diameter: 1.0 in (25.4 mm) |

| Motorized Z Axis Lifting Capacity | 20 lbs (9 kg) |

| Available Focus Lenses | 2.0 in (50 mm) HPDFO™ (High Power Density Focusing Optics) |

| Laser Platform Interface Panel | Five button keypad |

| Computer Requirements | Requires dedicated PC with Windows® 7/8/10 32/64 bit and one available USB port (2.0 or higher) |

| Optics Protection | Integrated with included gas assist |

| Cabinet Style | Desktop |

| Laser Options | 10, 30, 40, 50 and 60 Watts |

| Weight | 95 lbs (43 kg) |

| Power Requirements | 110V/10A 220V-240V/5A |

| Exhaust Requirements | One 3 in (76 mm) port 250 CFM @ 6 in static pressure (425 m3/hr at 1.5 kPa) |

| Material | Engrave | Cut |

|---|---|---|

| ABS Plastic | • | • |

| Acrylic | • | • |

| Avonite | • | • |

| Brick | • | |

| Cardboard | • | • |

| Ceramic | • | |

| Chipboard | • | • |

| Corian® | • | |

| Cork | • | • |

| Delrin® | • | • |

| Fabric | • | • |

| Fiberglass | • | |

| Foam | • | • |

| Fountainhead | • | • |

| Glass | • | |

| Granite | • | |

| Kevlar | • | • |

| Laminated | • | • |

| Plastics | • | • |

| Leather | • | |

| Marble | • | |

| Masonite® | • | • |

| Mat Board |

| Material | Engrave | Cut |

|---|---|---|

| Melamine | • | • |

| Mother of Pearl | • | • |

| MDF | • | • |

| Mylar® | • | • |

| Nylon | • | • |

| Paper | • | • |

| Particle Board | • | |

| Polycarbonate | • | • |

| Polypropylene | • | • |

| Polyester | • | • |

| Pressboard | • | • |

| Resin | • | • |

| Rubber | • | • |

| Silicone | • | • |

| Silk | • | |

| Stone | • | |

| Styrene | • | |

| Tile | • | |

| Travertine | • | • |

| Twill | • | • |

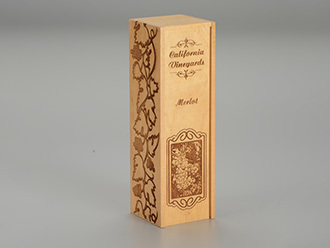

| Wood |

GUIDELINE: 10 WATTS CAN CUT APPROXIMATELY 1/8”; 25 WATTS CAN CUT APPROXIMATELY 1/4”; 50 WATTS CAN CUT APPROXIMATELY 1/2”; 100 WATTS CAN CUT APPROXIMATELY 3/4”.

| Material | Direct1 | MMC2 |

|---|---|---|

| Alum-A-Mark | • | |

| Aluminum | • | |

| Anodized | • | |

| Aluminum | • | |

| Brass | • | • |

| Carbide | • | |

| Cobalt | • | |

| Copper | • | • |

| Iron |

| Material | Direct1 | MMC2 |

|---|---|---|

| Nickel | • | |

| Painted | • | |

| Brass | • | • |

| Pewter | • | • |

| Stainless | • | • |

| Steel | • | • |

| Steel | • | |

| Titanium | ||

| Tungsten |

Air Dryer

Removes moisture from air assist which can damage laser optics. Allows air assist to operate even in humid environments. Suggested for use with the Compressed Air Unit.

Computer-Controlled Compressed Air Unit

Supplies dry, oil-free compressed air to enable air assisted cutting and engraving and extends the life of the laser system optics. The compressed air unit is controlled through the Versa Laser and turns on automatically when a job is in process. The compressor pump is noise-insulated for quiet operation.

Rotary Fixture Attachment

The rotary attachment accommodates most cylindrical items up to 5 inches in diameter and can be installed or removed without the need to restart the system. Holds part on both ends and can be run in high speed raster mode with lighter objects and also runs in vector mode. Rotates beyond 360 degrees in order to assure full wrap-around engraving. Loading and unloading is quick and easy. A sensor detects the rotary attachment when installed and automatically makes all of the adjustments necessary for rotary marking and engraving.

Air Assist Back Sweep

Recommended for use with the Computer-Controlled Compressed Air Unit, the Back Sweep attachment directs high pressure air or inert gas toward the exhaust duct to suppress flaming and evacuate smoke, fumes and debris away from the material being processed. This is particularly useful for jobs that require deep cutting and for rubber or other materials that produce a lot of dust and debris during the engraving process.

Integrated Cart

Moveable floor standing unit combines stylish good looks with durable construction for years of dependable service. Two large drawers provide generous storage; caster wheels offer moving convenience.

High Power Density Focusing Optics (HPDFO)™

Exclusive, patented optics increase the power density of the laser to achieve dramatically improved resolution for applications requiring extremely fine details. HPDFO makes it possible to engrave smaller text, produce higher resolution graphics and allows direct marking on some uncoated metals, including iron, stainless steel, chrome steel and titanium, without the need for metal marking compounds.

Downdraft Honeycomb Cutting Table

Provides a low contact area cutting surface with minimal back reflection and light vacuum hold-down. Removes smoke from below cut, reducing potential of damage to bottom surface of material and improves cutting quality. A sensor detects the presence of cutting table when it’s installed and automatically adjusts the Z-axis to place materials at the proper focus. Greatly reduces need to clean work table.

Air Assist Cone

The Air Assist Cone directs a jet of compressed air onto the material being processed to suppress flaming, thus improving cutting and engraving quality. Suggested for use with the Computer-Controlled Compressed Air Unit.

Computer Controlled Air Cleaner/Cart

Air filtration device removes smoke and fumes from VersaLaser when external venting is not possible. Cart is controlled through the VersaLaser and automatically powers on/off when a job is in process. Moveable floor standing unit offers the same sleek design and durable construction as the Integrated Cart minus the storage.