PLS 6.150D

Uniquely Universal Features

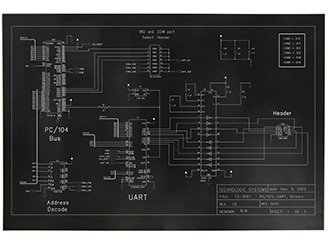

Laser Interface+™

Universal Laser Systems has developed the world’s most advanced, powerful and flexible laser print driver.

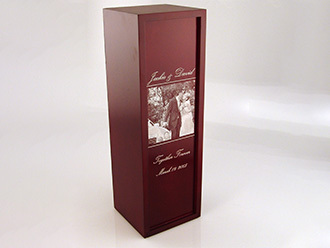

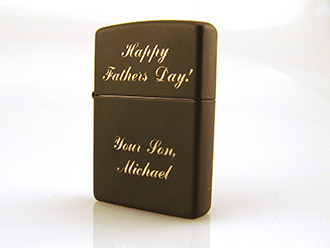

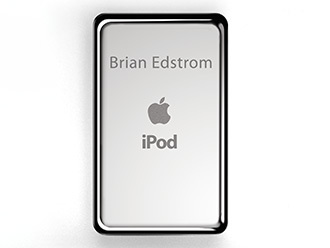

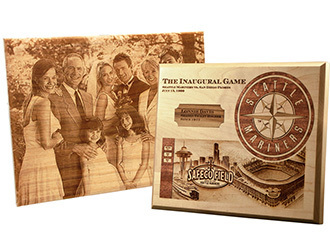

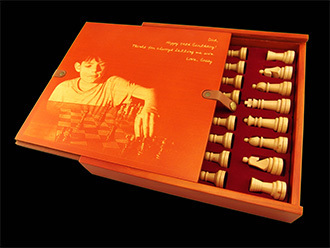

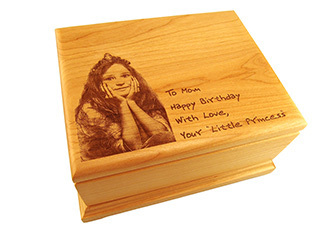

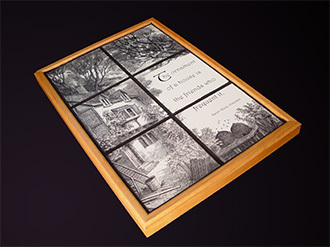

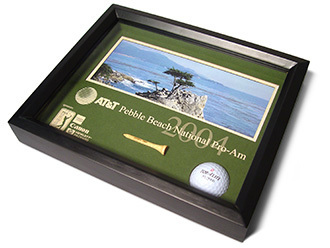

1-Touch Laser Photo™

We developed this software to make any photographic image suitable for laser engraving.

Universal Laser Cartridges

Our exclusive line of patented CO2 Free-Space Gas Slab Lasers is designed specifically for the needs of laser cutting, engraving, graphic imaging and marking applications.

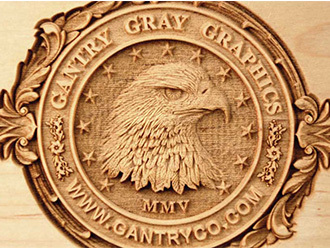

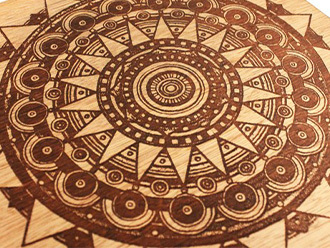

High Power Density Focusing Optics™

These optics allow the laser beam to be focused to a much smaller spot, producing sharper images at tighter tolerances.

Rapid Reconfiguration™ of Lasers

Laser Interface+™

Universal Laser Systems has developed the world’s most advanced, powerful and flexible laser print driver.

1-Touch Laser Photo™

We developed this software to make any photographic image suitable for laser engraving.

Universal Laser Cartridges

Our exclusive line of patented CO2 Free-Space Gas Slab Lasers is designed specifically for the needs of laser cutting, engraving, graphic imaging and marking applications.

High Power Density Focusing Optics™

These optics allow the laser beam to be focused to a much smaller spot, producing sharper images at tighter tolerances.

Rapid Reconfiguration™ of Lasers

Every laser cartridge we produce is factory pre-aligned for easy integration into any of our laser platforms.

Dual Laser Configurations

Giving you the ability to merge two independent laser sources into a single beam for additional power and flexibility.

System Features

- Laminated Safety Glass

- Over-temp Alarm (for fire safety)

- Multiple Automatic Focusing Modes

- Precision Digital Motors

- Multiple Language Support

- Permanently Sealed Bearings

- Proportional Pulse Control

- Stretch-Free Kevlar® Belts

Laser Features

- Laser Fan Control (to reduce noise)

- Smart Lasers

- Laser Pointer

- Wide Selection of Power Levels

- Air-Cooled Laser Cartridge

- Patented Permalign™

- No Optical Beam Alignment Required

- Patented Cross-Platform Compatibility

- Patented Free-Space Gas Slab Laser Design

- High Reliability, Excellent Power Stability

- Warranty Available Up To 5 Years

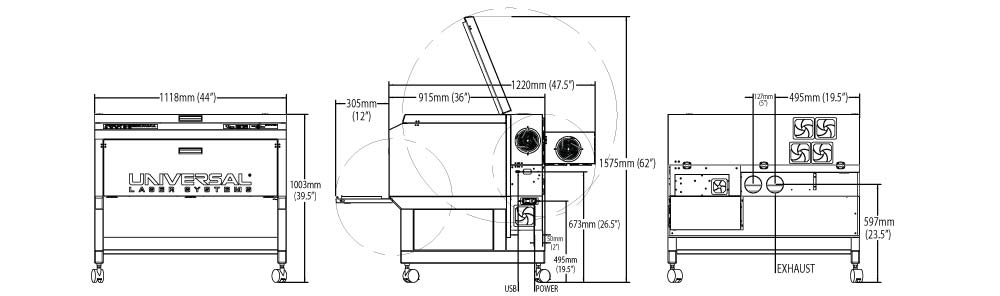

Platform Specifications

| PLS 6.150D | |

| Laser Material Processing Area (W x H) | 32 x 18 in (813 x 457 mm) |

| Maximum Part Size (W x H x D) | 37 x 23 x 8.5 in (940 x 584 x 216 mm) |

| Overall Dimension (W x H x D) | 44 x 39 x 36 in (1118 x 991 x 914 mm) |

| Rotary Capacity | Max Diameter 8 in (203 mm) |

| Motorized Z Axis Lifting Capacity | 40 lbs (18 kg) |

| Available Focus Lenses | 2.0 in (51 mm) HPDFO™ (High Power Density Focusing Optics) |

| Laser Platform Interface Panel | Keypad and LCD display show current file name, laser power, engraving speed, PPI and run time. |

| Computer Requirements | Requires dedicated PC with Windows® 7/8/10 32/64 bit and one available USB port (2.0 or higher) |

| Optics Protection | Integrated with included Gas Assist |

| Cabinet Style | Free-Standing |

| Laser Options | 10, 30, 40, 50, 60 and 75 watts Equipped for two lasers – must be of equal power |

| Weight | 345 lbs (156 kg) |

| Power Requirements | 220V-240V/15A |

| Exhaust Requirements | Two 4 in (102 mm) ports 500 CFM @ 6 in static pressure (850 m3/hr at 1.5 kPa) |

| Material | Engrave | Cut |

|---|---|---|

| ABS Plastic | • | • |

| Acrylic | • | • |

| Avonite | • | • |

| Brick | • | |

| Cardboard | • | • |

| Ceramic | • | |

| Chipboard | • | • |

| Corian® | • | |

| Cork | • | • |

| Delrin® | • | • |

| Fabric | • | • |

| Fiberglass | • | |

| Foam | • | • |

| Fountainhead | • | • |

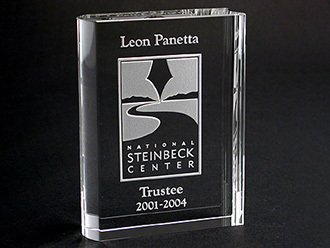

| Glass | • | |

| Granite | • | |

| Kevlar | • | • |

| Laminated | • | • |

| Plastics | • | • |

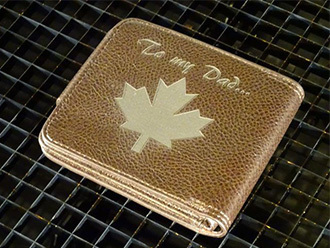

| Leather | • | |

| Marble | • | |

| Masonite® | • | • |

| Mat Board |

| Material | Engrave | Cut |

|---|---|---|

| Melamine | • | • |

| Mother of Pearl | • | • |

| MDF | • | • |

| Mylar® | • | • |

| Nylon | • | • |

| Paper | • | • |

| Particle Board | • | |

| Polycarbonate | • | • |

| Polypropylene | • | • |

| Polyester | • | • |

| Pressboard | • | • |

| Resin | • | • |

| Rubber | • | • |

| Silicone | • | • |

| Silk | • | |

| Stone | • | |

| Styrene | • | |

| Tile | • | |

| Travertine | • | • |

| Twill | • | • |

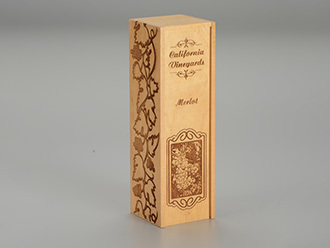

| Wood |

GUIDELINE: 10 WATTS CAN CUT APPROXIMATELY 1/8”; 25 WATTS CAN CUT APPROXIMATELY 1/4”; 50 WATTS CAN CUT APPROXIMATELY 1/2”; 100 WATTS CAN CUT APPROXIMATELY 3/4”.

| Material | Direct1 | MMC2 |

|---|---|---|

| Alum-A-Mark | • | |

| Aluminum | • | |

| Anodized | • | |

| Aluminum | • | |

| Brass | • | • |

| Carbide | • | |

| Cobalt | • | |

| Copper | • | • |

| Iron |

| Material | Direct1 | MMC2 |

|---|---|---|

| Nickel | • | |

| Painted | • | |

| Brass | • | • |

| Pewter | • | • |

| Stainless | • | • |

| Steel | • | • |

| Steel | • | |

| Titanium | ||

| Tungsten |

Air Dryer

Computer-Controlled Compressed Air Unit

Rotary Fixture Attachment

Air Assist Back Sweep

Integrated Cart

High Power Density Focusing Optics (HPDFO)™

Downdraft Honeycomb Cutting Table

Air Assist Cone

Computer Controlled Air Cleaner/Cart