ULTRA X6000

The ULTRA X6000 platform offers laser material processing for the widest possible range of materials. It is designed and ideally suited for precision material processing in manufacturing, research and development, academic research, and prototyping environments. With its unique modular architecture, customizable solutions can be easily reconfigured with a wide array of options for enhancing performance, capability, and safety to complete the perfect solution to meet present and future business needs.

The ULTRA X6000 platform has a materials processing envelope of 36 x 24 in (914 x 610 mm), with support for materials with a thickness up to 12 in (305 mm).

Configure the customizable ULTRA X6000 platform with up to three laser sources consisting of two interchangeable CO2 lasers and one fiber laser. When the platform is configured with three lasers, users can take full advantage of MultiWave Hybrid™ technology enabling up to three wavelengths – 9.3 µm, 10.6 µm, and 1.06 µm – to be simultaneously combined into a single coaxial beam. Each spectral component of the beam is independently controlled and can be modulated in real time.

Major features include multiple laser support, rapid high-accuracy laser beam positioning, precision material-independent autofocus, controllable laser power density, an automation interface, camera registration, an integrated touch screen control panel, over temperature detection, and support for fire suppression.

| ULTRA X6000 | |

TECHNOLOGIES | |

| Camera Registration | A feature that aligns a control file to registration marks or features on the surface of a material. Compensates for scale, skew, and perspective. |

| Precision Material Independent Autofocus | Repeatability of ± .0025 in. (63.5 μm) using motorized focus assembly and high-resolution touch sensor. |

| SuperSpeed™ Technology * | A patented feature that produces two focal spots (one for each laser beam) to enable the system to deliver two independently controlled raster lines at a time. SuperSpeed requires a laser system equipped with two CO2 lasers of the same wavelength and power. |

| Multi-Wave Hybrid™ Technology * | A patented technology that enables a combination of laser wavelengths (up to three wavelengths) to be focused to the same focal point within the same focal plane and used either sequentially or simultaneously. |

| Rapid Reconfiguration™ | A patented technology that enables users to install and reinstall any supported ULS CO2 laser source onto any ULS laser system without tools and optical alignment to optimize laser processing for the widest variety of materials. |

| Intelligent Materials Database | A powerful and unique database that generates laser processing parameters for a wide variety of materials and laser system configurations. If the system configuration changes, the database automatically recalculates the parameter values. |

| 21” Touch Screen Control Panel | A fully integrated 21” (533 mm) touch panel command and control console used to control laser system operation. Eliminates the need for a separate control computer. |

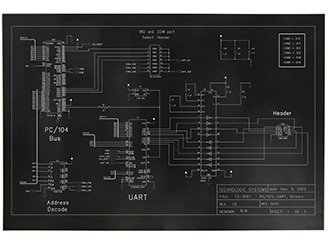

| Automation Interface | An addressable device that can receive input signals and provide output signals. Enables the laser system to control external devices and allows external devices to initiate laser system functions. |

| Laser System Manager (LSM) | An advanced user interface with a high degree of functionality and control that allows users to efficiently manage design files and laser material processing parameters. |

| Industry Standard Interchange Format Support | A software feature that supports industry standard graphic interchange formats including DXF, PDF, and G-Code. |

| Design File Relocation and Duplication Controls | A set of user controls to reposition or duplicate design files anywhere within the material processing field. |

| Kerf Compensation | A user adjustable control that compensates for material width removed during laser cutting in order to achieve desired dimensions without changing the design file. It maintains true arc and circle geometry if present in the design. |

| Vector Acceleration Control | A user adjustable control to define acceleration of vector motion for each control file. |

| User Access Administration | A software administration feature for managing multiple user accounts and permissions. |

| Dynamic Energy Stabilization | A feature that maintains even laser energy delivery regardless of the speed of the motion system. |

| True Position Laser Pulsing | A feature that provides optimal laser pulse placement driven by positional feedback from synchronized multi-axis linear encoders. |

| Intelligent Path Planner | A comprehensive path planning algorithm that minimizes laser processing completion time. |

| True Width Raster Processing | A feature that eliminates the need for motion system over-travel beyond the edges of the raster image. |

| Design File Geometry Preservation | A feature that maintains curves in a design file, i.e., circles, ellipses, b-splines, Beziers, and NURBS, and ensures curves are kept throughout the path planning process rather than using linear interpolation. |

| Line Segment Reduction | A user control to reduce excessive line segmentation contained in some design files. |

| Path Deviation Control | A user control to adjust the allowable deviation from the intended path to increase throughput. |

OPTICS | |

| Controllable Laser Power Density 4X 1X / 13X * | A patent pending feature that provides the unique ability to control laser power densities while maintaining a high degree of alignment accuracy of the focal plane with the material surface as well as a Gaussian beam distribution. Power Densities: 1X (Available), 4X (Included) or 13X (Available) for 10.6 μm and 9.3 μm wavelengths; 52X for 1.06 μm Fiber wavelength (Included). Normalized power density (watts/cm2) = power density coefficient x 103 x average laser power (watts). Normalized power density is the power of the material processing laser(s) divided by the area of the focal spot measured at 1/e2. |

GAS ASSIST | |

| Programmable Gas Assist | A feature that allows the user to program gas type and flow rate on a process-by-process basis within a control file. |

| Optics Protection | A barrier of clean air that protects optical components during processing. |

| Coaxial Gas Assist Attachment | A gas assist attachment that directs air (or gas) perpendicular to the material’s surface. |

| Lateral Gas Assist Attachment * | An adjustable gas assist attachment that directs air (or gas) laterally or at an angle to the material’s surface. |

| Air Compressor * | A compressed air source that delivers optimally conditioned, clean, dry, and oil-free air for optics protection and gas-assisted laser processing. |

MATERIAL HANDLING | |

| Multifunction Material Support Structure | A built-in aluminum honeycomb work surface designed to keep materials stationary and in focus during laser processing. Reduces back reflection and enables exhaust of laser processing byproducts from underneath materials. Includes a full-field masking material dispenser. Configurable using Machined Aluminum Tiles, Material Support Pins and Vacuum Booster. |

| Machined Aluminum Tiles * | An accessory that provides a rigid and smooth work surface for laser material processing. When used with cutting processes, the compatible Material Support Pins are recommended. |

| Material Support Pins * | A set of custom machined pins for laser cutting that can be inserted into either the Multifunction Material Support Structure or the Machined Aluminum Tiles. Pins add sufficient space between the target material and the work surface to eliminate back reflection. |

| Vacuum Booster * | An external accessory that dramatically increases the pressure differential between the material support surface of the Multifunction Material Support Structure and ambient/atmospheric pressure to keep materials stationary. |

| Class 4 Conversion Module for Pass-Through * | A patented technology that enables the laser system to facilitate material pass-through in compliance with CDRH and international safety regulations for operating Class 4 laser systems. This optional, add-on module converts a fully enclosed Class 1 system into an open Class 4 system. |

| Rotary Axis Module * | An accessory that enables 360° rotation laser processing of cylinders, spherically-shaped, and tapered objects. The addressable resolution is 13 arc seconds. |

AIR FILTRATION and HANDLING | |

| Intelligent Air Filtration UAC 4000 * | An external accessory that uses a patented dual carbon filter and sensor suite (for CO and VOCs) that filters out laser processing byproducts, monitors filtration performance at every stage, and alerts the operator when predefined contaminant thresholds have been reached. Connects directly to the laser system to turn filtration on and off with laser processing and communicates the status of all aspects of the UAC 4000. |

SAFETY and FACILITY | |

| Overtemperature Detection | A safety feature designed to disable all laser sources, home the motion system, and trigger an audible alarm in the event it detects an unusually high temperature in the laser processing area. |

| Safety Interlocks | A safety feature that disables the laser source when access doors are open as required by all major international safety standards. |

| Laser Blocking Laminated Safety Glass | A shatterproof multi-layer laminated safety glass with appropriate wavelength filter media. Meets laser safety requirements OD 5+ for 10.6 μm , 9.3 μm and 1.06 μm wavelength laser radiation. |

| Metal Enclosure with Labyrinth Seals | A design feature consisting of overlapping flanges that all enclosure doors or access panels must have to prevent direct line of sight into the enclosure, as required by international safety regulations. |

| E-Stop | A highly visible standards-compliant pushbutton. Once depressed, DC power to all laser sources, the motion system, and other control mechanisms are immediately shut off, while aborting all system operations. |

| Fire Suppression * | A patented accessory that deploys fire suppressant into the laser material processing area if self-sustained combustion is detected. |

| Collision Detection | A feature that immediately stops and disables servo motors In the event an obstruction interferes with the motion system from any direction or axis. |

| Light Tower | A set of color-coded lights mounted atop a pole used to indicate the laser system status to personnel in visual proximity of the laser system. |

SPECIFICATIONS | |

| Material Processing Envelope (X,Y,Z) | 36 x 24 x 12 in. (914 x 610 x 305 mm) |

| Minimum Addressable Beam Positioning | 2 μm (.00008 in.) beam position addressability |

| Maximum Effective Raster Material Processing Speed | >300 in./sec (7620 mm/sec) [Requires SuperSpeed™ operation] |

| Multiple Laser Support | UP TO 3 LASER SOURCES CAN BE USED INDIVIDUALLY OR IN COMBINATION Laser Sources Available

Laser Sources Combinations

SUPPORTS RAPID RECONFIGURATION OF CO2 LASERS |

| Maximum Laser Power | CO2: 300 watts Fiber: 50 watts |

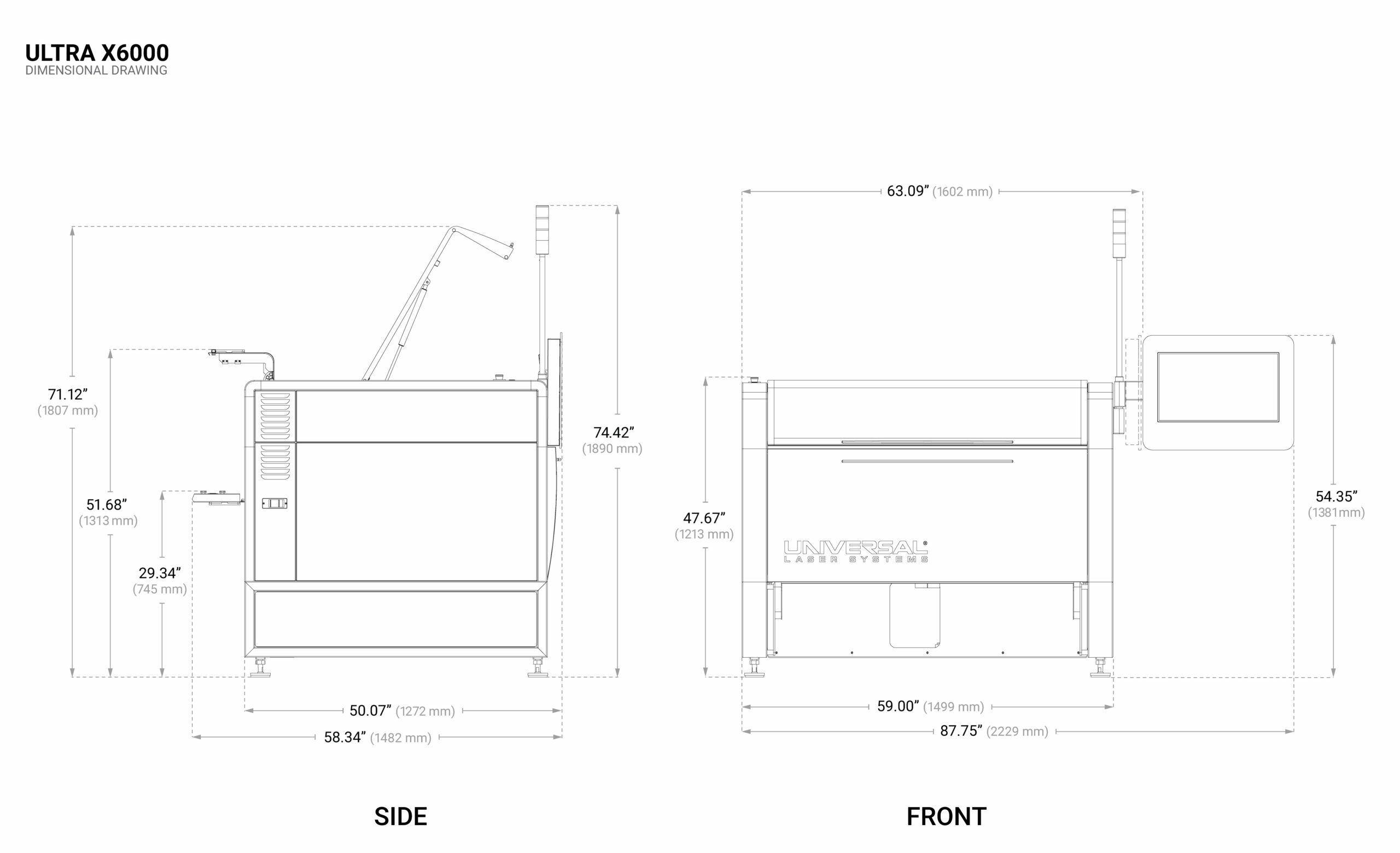

| System External Dimensions | Width: 63.09 in. (1603 mm) with Control Panel folded 87.75 in. (2229 mm) with Control Panel extended Depth: 50.07 in. (1272 mm) Height: 47.67 in. (1219 mm) to top of enclosure 74.42 in. (1890mm) to top of Light Tower |

| Weight | 550 lbs (250 Kg) |

| Power Requirements | 220V-240V/20A (300 Watt configuration requires high power kit and 30A) |

| Exhaust Requirements | Intelligent Air Filtration (UAC 4000) or External Exhaust Blower Capable of >700 CFM at 6 in. WG Static Pressure (1190 m3/hr. at 1.5 kPa) 6 in. (152mm) Exhaust Port |

| Computer Requirements | Not required; includes integrated 21” Touch Screen Control Panel |

| Laser Safety Classification | Class 1 for material processing lasers Class 2 overall due to red laser pointer Can convert to Class 4 with optional Class 4 module |

| NOTES | Weight is approximate and varies with laser source selection * Available feature |